In Your Community

Helping the Atakapa Ishak Chawasha Tribe Protect What Matters Most

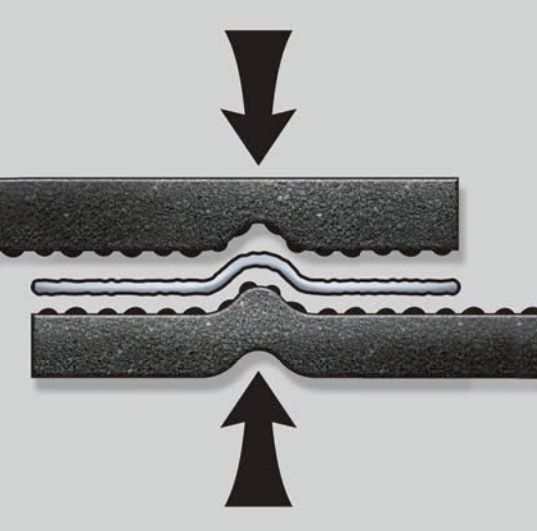

The Louisiana coast has seen several severe weather events in the last decade, which has made it difficult for many people to rebuild their homes and prepare for future storms. This was the case for the Atakapa Ishak Chawasha tribe, a small community accessible only by boat.The group Rebuilding Together New Orleans recognized the impact a joint effort could have on the region. Together with the GAF Community Matters initiative, and roofing contractor Sunbelt Roofs, the group collaborated with the Atakapa Ishak Chawasha tribe to replace five hurricane-damaged roofs in the tribe's coastal Louisiana homeland.Sowing ResilienceThe week-long roof rebuilding initiative was part of the GAF Community Matters commitment to repair or replace 500 roofs throughout the Gulf region. The goal was to further strengthen and empower the resilience of the families, shelters, and livelihoods of the coastal Atakapa Ishak Chawasha tribe.The Timberline HDZ® RoofCycle™ Series Shingle, which is made with recycled material, was used to protect these homes.Adapting Environmentally"We are stewards of the environment," said Rosina Philippe, a tribal elder of the Atakapa Ishak Chawasha tribe, as she spoke with GAF during the week-long rebuilding initiative. Over a millennium, the tribe has resided in the region, finding all it needs to feed and sustain itself from the environment.However, man-made conditions have significantly impacted the tribe's way of life. The once-forested coastal region is now a salt marsh area, devoid of fresh water and trees, due to levees along the Mississippi River and canals cut through the coastal landscape.These changes have made it "more of a challenge to find the food and plants and medicines that we depend on for our livelihood. But we have been finding them, propagating them, and sharing them with other tribes," said Philippe. "Our way is to accept the natural processes, not change them."Fortifying against Unpredictable WeatherIn addition to the tribe's changing landscape, "what we're dealing with is the unpredictability of the weather," said Philippe. Climate change can cause dramatic temperature swings, which can impact everything from the life cycle of the tribe's crops to the protection of its homes.Situated at the southeasternmost lands of Plaquemines Parish, fingerlike marshland trails out into the Gulf. The homes in the Atakapa Ishak Chawasha community are built on stilts along these watery paths and are accessible only by boat. These homes are often the first line of impact with hurricanes that rip through the Gulf of Mexico.Hurricane Ida—the fifth most expensive hurricane in US history—dealt the water-based community a devastating blow. For nearly two years, the hurricane's impact on tribal homes compounded with each subsequent storm because there wasn't an opportunity to repair its damage.Partnering for StrengthFortunately, through collaborative efforts between the Atakapa Ishak Chawasha, Rebuilding Together New Orleans, GAF, and Sunbelt Roofs, the opportunity to build tribal community resilience through new roofs became available. Bringing in roofing materials and roofers by boat, the Sunbelt Roofs team removed the storm- and hurricane-damaged roofs, repaired roof decking as needed, and installed new GAF roofing systems on the five homes.The roofing materials installed are designed to protect against volatile weather like hurricanes. To provide long-lasting protection against leaks and wind-driven rain, Sunbelt Roofs installed StormGuard® Film-Surfaced Leak Barrier and FeltBuster® Synthetic Roofing Felt. To help prevent shingle blow-off due to high-speed winds, Sunbelt Roofs installed Pro-Start® Starter Strip Shingles.The Timberline HDZ® RoofCycle™ Series shingles that were installed have Dura Grip™ Adhesive, which provides advanced protection from shingle blow-off and wind-driven water creating leaks or water damage.Building Communities TogetherThe initiative with the Atakapa Ishak Chawasha tribe is part of a comprehensive $25 million GAF commitment through 2025 to leverage roofing expertise, resources, and products to help support and empower resilient communities' fundamental needs. Through grants, in-kind donations, and hands-on support, GAF Community Matters is partnering with area organizations that know their communities' needs best.In the Gulf region, GAF partnered with organizations such as Rebuilding Together New Orleans, SBP, Good360, Habitat for Humanity, and Team Rubicon to rebuild or repair 500 Gulf region roofs, train a skilled workforce, and empower communities hard-hit by severe weather.Moving ForwardDespite the challenges of climate change and the changes in their physical landscape, Philippe said, "We still live a rich life here." As the environment changes, the tribe adapts, a demonstration of its resiliency. "These are the new norms that we are having to learn and document and chronicle, this is the information we'll have to pass onto our future generations so that they can continue to inhabit this area," she explained.To learn more about the resiliency work at GAF or to get involved, explore the GAF Community Matters initiative. Special thanks to the Atakapa Ishak Chawasha tribe, a member of the First People's Conservation Council of Louisiana.

By Authors Annie Crawford

April 16, 2024